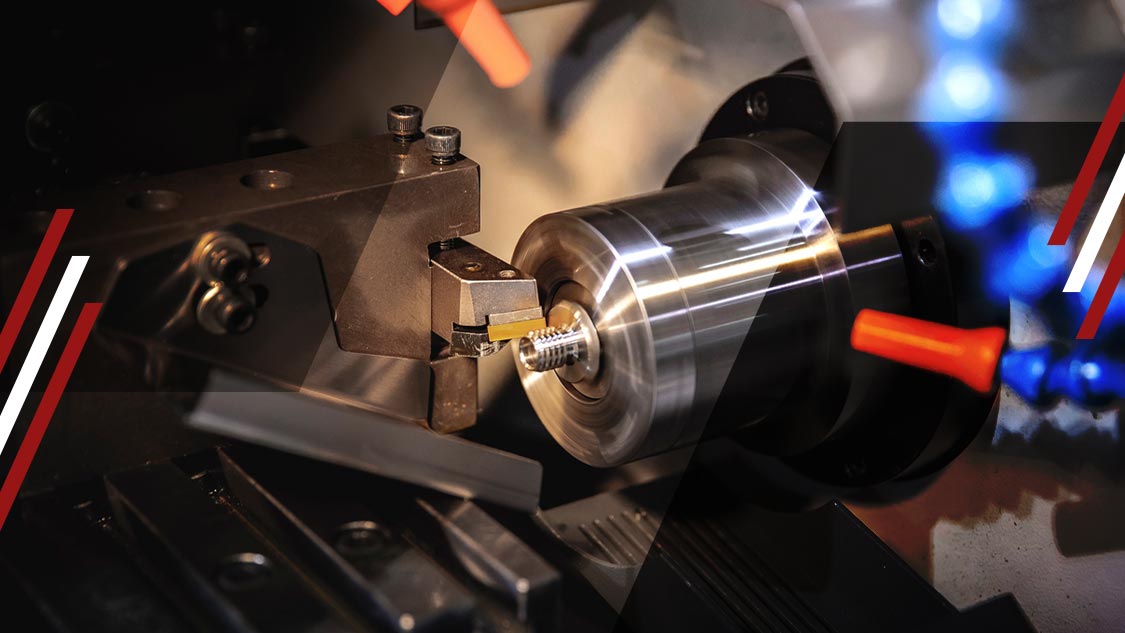

The surface finishing process is the final step in CNC machining. Different techniques remove surface irregularities, improve the part’s appearance and add strength and resistance to increase functionality. The finishing technique you use depends on specific requirements, like industry standards, the part’s application and the material you’re working with.

At American Micro Industries, we are quality driven and ready to customize parts for various utilizations. Whether you’re adhering to tight dimensional tolerances and smooth finishes or require additional corrosion and wear resistance, our surface finishes for CNC machining can produce what you need.

CNC machining is subtractive, which can leave tool marks or surface imperfections on final parts. Standard surface finishes for CNC machined parts decrease roughness, wear resistance and other cosmetic properties of customized metal parts while also improving aesthetics and functionality.

Some common types of surface finishes include:

If you’re working with plastic or a similar non-metal material, choose your surface finish carefully. Note the material and the component’s application, texture and strength, and avoid high heat or heavy impact-based techniques on softer components.

These are some common machining finishes for plastic and similar materials — consider each finish to determine which solution best matches your requirements and preferences.

As-machined parts are fresh off the line with minor tool marks and average surface roughness, and many are molded to already have a specific texture or finished look. A component’s average roughness (Ra) is the difference between the actual machining and ideal machining surface roughness, which can vary depending on the use case.

The benefits of an as-machined finish include consistency between multiple units and the tightest dimensional tolerances. Capable of supporting any material, as-machined finishes are great for parts that demand extremely tight tolerances and dimensional integrity as opposed to aesthetics. A downfall of this surface finish is having visible tool marks on your final part that also lacks a protective coating.

Bead blasting is a finishing technique that blasts parts with small glass beads through a pressurized air gun. This process mainly improves aesthetics to create a matte or satin finish with a light texture. It’s a type of primary finish that mechanically alters the surface to change or remove machining marks by removing excess material, resulting in a smooth surface.

An advantage of bead blasting is its uniform and textured finish. However, it doesn’t have much of an effect on tolerances and can affect the surface’s critical dimensions. It’s also a manual process that can change in terms of both air pressure and the size of glass beads, so the results aren’t always identical.

If bead blasting plastic components, make sure they can withstand the impact. If not, consider injection molding as an alternative way to achieve a matte finish.

Wet sanding is ideal for finishing plastic components to prepare them for painting or clear-coat polish. The process involves using fine-grit silicon carbide sandpaper soaked in water before gently sanding in circular motions. Transitioning from a moderate to low coarse sandpaper helps finish the parts with a smoother surface.

Once smooth, you can apply and buff a plastic-safe clear-coat polish to promote shine and sheen.

Fire polishing isn’t the right fit for all plastic and glass components, but if the materials can withstand the temperatures, it’s a highly effective way to finish CNC parts. Operators use an open flame to melt the part’s surface layer, keeping the fire at a specific temperature and angle throughout. As the surface reaches a partial melting point, it starts to tense and shift, creating a smooth, polished surface.

Depending on the material you’re finishing, fire polishing could turn parts with a cloudy finish into a clear, flattened finish. Fire polishing also reduces any bumps or ridges formed during the production process.

Because fire polishing involves an open flame and careful application, it’s best left to trained professionals with previous experience working on plastic CNC components.

Polishing plastic with a chemical vapor is an effective method for clarifying matte, opaque or dull plastics, leaving the final part smooth and shiny. You can use the polishing wheel to smooth edges and inconsistencies while enhancing the material’s natural qualities. CNC parts with highly visible imperfections might need sanding before applying the vapor polish.

Yes, you can combine different CNC surface finishes to take advantage of their different properties. For example, bead blasting helps create a specific matte texture before applying another finish.

The last phase of the CNC machining process is surface finishing to remove defects from parts for a smooth and aesthetic surface while forging stronger parts more resistant to corrosion and wear.

While surface roughness and surface finish describe the part’s physical surface, surface finishing refers to the specific process of creating a smooth and strong surface. Some methods add material while others are subtractive or use heat and other techniques to alter the surface.

Surface finish typically comprises three characteristics, including a component’s lay, roughness and waviness.

In some cases, you may need to mask holes and other critical areas before surface finishing a CNC part. Masking protects the surface or hole from additional layers that add thickness and can interfere with the part’s tight tolerances and other components, like press fits and threaded holes.

Components with holes should be plugged with rubber or masking lacquer. These are removed once the finishing process is complete and has had enough time to cure properly.

Some surface finishing techniques are more involved than others. For example, wet sanding a plastic component typically requires wiping and resetting the applicator throughout the process, while flame and vapor polishing need less hands-on involvement.

Before selecting and applying a surface finish, consider how each part will interact with other components, including how often they will touch and with how much force or resistance. This will help you choose the right level of surface protection to keep components structurally sound after processing.

Understanding the surface finishes your parts require to look and function their best takes consideration and support from the experts. American Micro Industries focuses on individual, customized pieces made to your specifications that exceed expectations. Through incredible attention to detail and on-time deliveries, we have endless capabilities to create replacement or new custom parts for your applications.

Learn more about our surface finishes for CNC machining, or request a free quote today.