American Micro Industries’ extensive phenolic machining capabilities encompass a wide range of materials. As a partner to manufacturers across the country, we can turn around projects around with a high degree of speed and accuracy. Leveraging technology, industry expertise and a commitment to customer service, we help our clients find smart solutions that build better products.

On this page, you’ll find information about some of the many CNC phenolics we work with. Keep reading for details or get in touch with one of our representatives to learn more, request a quote.

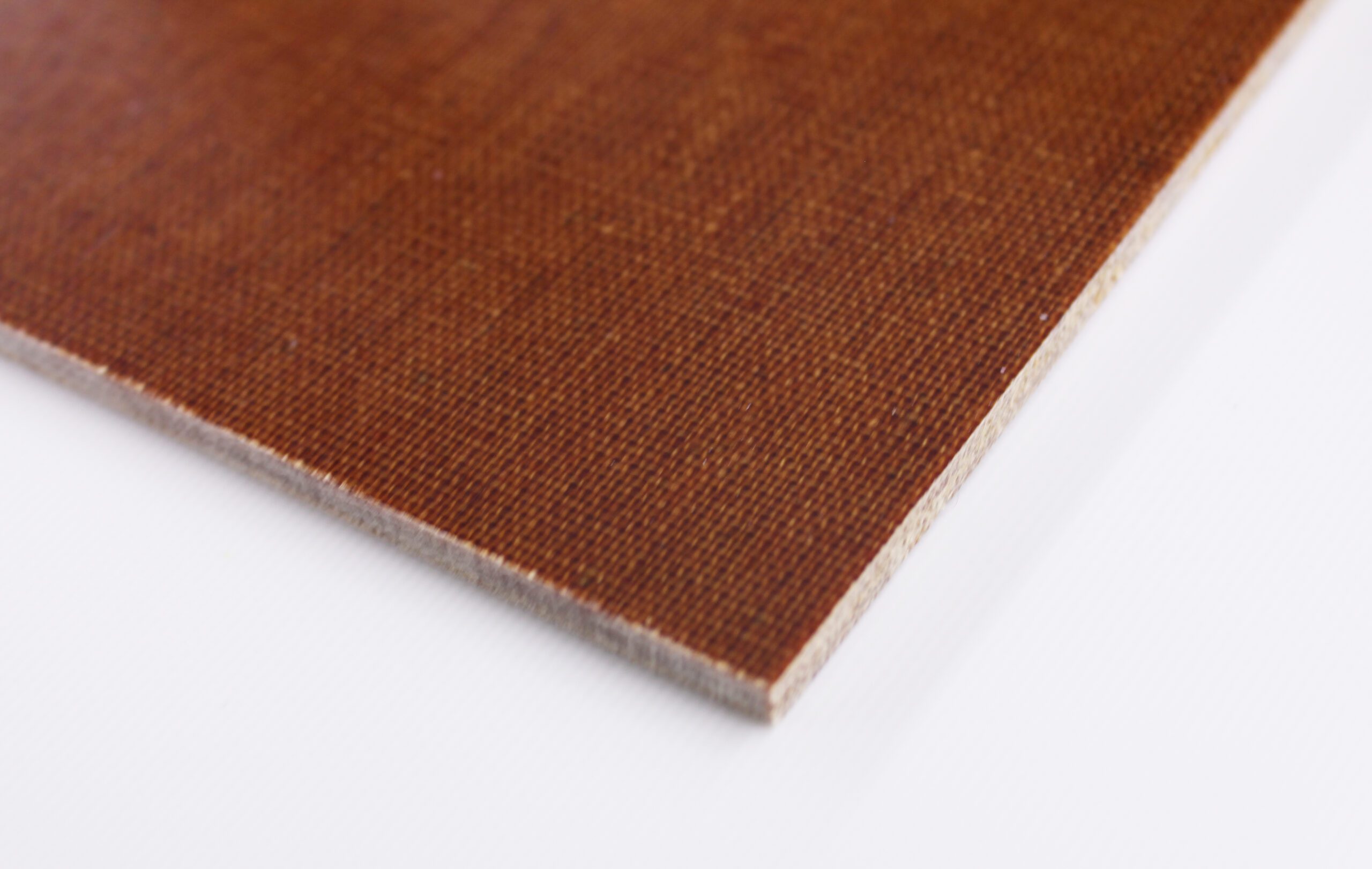

LE phenolics are similar to CE phenolics but made from linen cotton cloth with a finer weave. As a result, they offer a better finish than CE, in addition to improved machining characteristics that make them suitable for highly precise components.

Like CE phenolics, LE phenolics have good mechanical properties and dimensional stability. They also meet MIL-I-24768/13 FBE requirements. Because LE phenolics are thinner, they are suitable for a wider range of potential applications, including panels, terminal strips, ball bearing retainers and fine gears.

If you’d like to learn more about our LE phenolic machining capabilities or request a quote for a project, contact the AMI office by phone or email.

LE Phenolic is available in:

CE phenolic is a fabricated reinforced laminate produced from a medium weave cotton cloth impregnated with a phenolic resin binder. The medium weave canvas yields good mechanical properties. However, it is not recommended for electrical primary insulation applications. CE phenolic meets Mil-I-24768/14 FBG requirements. It is available in sheet stock, rod, angle and U channel forms.

This cotton-canvas type material is frequently used in the manufacturing of pulleys, rollers, gears and guides. It also serves as electrical insulation in control boards. In addition to its good mechanical properties and toughness, CE phenolic offers high impact strength and exhibits good wear resistance; it is less abrasive than fiberglass when used in wear resistance applications. As with LE phenolic, this material can withstand temperatures of up to 285°F. CE phenolic machining is also a fairly easy procedure.

AMI is also capable of machining NEMA phenolics ranging from X Grade to XXX. NEMA X-grade phenolics are lightweight and strong, and offer excellent moisture- and impact-resistance. Mechanical and electrical grades are available in a range of thicknesses.

Each NEMA phenolic has different properties and different potential applications, including gears and gaskets used in aerospace, automotive and electronic manufacturing. NEMA sheet, strip, and rod phenolics are MIL-I-24768/11 compliant and meet UL 94HB specifications for flame retardance.

Accurately machining thin materials like Grade X phenolics requires specialized equipment and expertise. AMI can turn around large projects quickly, maintaining the accuracy you need to release a higher-quality finished product.

This phenolic material has the ability to fend off corrosion and is resistant to friction, abrasion, metal fatigue and many types of chemicals. NEMA XX can withstand temperatures of up to 257°F and features an impact strength of ASTM D732): .055 ft. lb/in. of notch. As with LE and CE phenolic, NEMA XX machining can be executed quickly and easily.

Also available:

Garolite G10/FR4 is one of the most versatile phenolics available and an excellent choice for a range of projects. First introduced in 1950 and now widely used in many industrial applications, G10/FR4 is a fire-resistant glass-reinforced epoxy laminate.

Notable characteristics of G10/FR4 include:

AMI is unique in our ability to mass-produce Garolite insulators for use in terminal boards, electrical and electronic test equipment, and electric rotors, among other demanding applications. Our approach emphasizes quality above all else, ensuring we can provide Garolite phenolic machining to your specifications.

G10/FR4 is just one of many Garolite phenolics we work with. Other excellent candidates for CNC machining include:

Finding the right phenolic laminate and knowing how to work with it takes deep industry expertise. AMI offers unmatched CNC machining capabilities that can drive your project’s success. We are one of the few companies capable of accurately turning around projects using G10/FR4, CE and LE phenolics, plus other nonmetallic laminates.

Check out our CNC machining Material Selection Guide for more information about the factors that go into selecting the best product for a given application.

At American Micro Industries, phenolics machining is one of our many areas of specialized expertise. We can provide custom precision CNC machined LE, CE and XX phenolic components that meet your specifications. In addition, we can produce custom Garolite® (fiberglass) parts that are a popular choice for many electrical insulation applications.

We offer turnkey CNC machining solutions that can provide customized results for each project. Our phenolic machining process begins by using your mechanical drawings to establish project parameters and determine the most suitable CNC machining technique. We can also develop a custom prototype prior to implementing a mass production process to ensure your part or component will meet your performance expectations. Our capable CNC staff will work closely with you to engineer and fabricate your custom parts and provide the turnkey solution you need to meet your quality and production goals.

We have a fully equipped machine shopping featuring CNC machinery and tooling. We also have a large CNC machining capacity that enables us to handle the biggest LE, CE and Nema XX machining jobs with ease. What’s more, we can perform various secondary machining procedures to provide the perfect finishing touch for your parts and components.

American Micro Industries has been in business since 1995. Over the course of more than two decades, we’ve grown to become the “go-to” manufacturer of high-quality custom parts and components for companies in industries such as Aerospace, Electronics, Automotive and Medical. Headquartered in Chambersburg, PA, we can meet the phenolics project needs for companies of all sizes throughout the USA.

No matter which phenolic material/production method you ultimately choose, you will get a finished product that will exceed your expectations. We specialize in the manufacturing of those hard-to-find parts that are typically unavailable from many of our competitors. We also strive to provide the fastest possible project turnaround time and prompt delivery to your facility. Our advanced logistics network enables us to process and ship orders in an expeditious manner, typically on the same or following day. It’s all part of our ongoing quest to achieve total satisfaction for every customer.

To learn more about our phenolics products and services or get a custom project quote, just give us a call at 1-866-774-9353 or fill out and submit our online contact form.