There are many forms of Garolite laminates, which can make choosing the right one for your job a challenge. This complete guide to Garolite laminates includes G10/FR4, G11/FR5, G5/G9, and G7. Discover how each grade of Garolite varies in mechanical strength, temperature resistance and electrical properties so you can find the materials for your project.

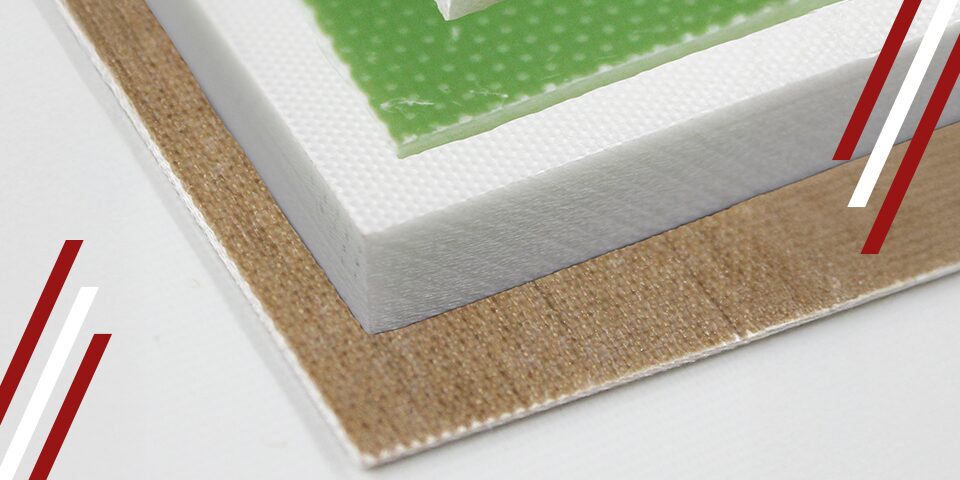

Garolite laminates are composite materials made from layers of substrate — usually glass — and resin cured under high pressure and heat. Also known as phenolic laminates, these thermoset materials are popular in many industries for several reasons, including mechanical strength, low moisture absorption and excellent electrical insulating capabilities.

As specified by the National Electrical Manufacturers Association, each Garolite grade varies by the resin and substrate it uses. The different makeups of each grade give it specific performance attributes to suit different jobs. One example is the maximum operating temperature. Epoxy resin-based grades like G11/FR5 can handle temperatures up to 355° F (179° C), whereas silicone resin laminates like G7 can tolerate up to 425° F (218° C).

Here’s an overview of the most common grades of Garolite, their key properties and main applications.

| Grade | Resin Type | Key Properties | Max Operating Temperature | Main Applications |

|---|---|---|---|---|

| G10/FR4 | Epoxy | General purpose, flame retardant | High | Electrical insulation, PCBs, structural parts |

| G11/FR5 | Epoxy | Strong in high temperatures | Higher | Aerospace, downhole drilling, high-temp fixtures |

| G5/G9 | Melamine | Highest arc resistance | High | Arc barriers, switchgear, power systems |

| G7 | Silicone | Highest heat resistance | Highest | Furnaces, high-heat gaskets, welding fixtures |

G10 is a tough, versatile laminate made from glass cloth and an epoxy resin. It has been widely used since the 1950s for its high strength and low moisture absorption. FR4 is flame-retardant as per UL 94 V-0 standards and is the industry standard for applications like printed circuit boards.

The key characteristics of G10/FR4 include:

Industries use G10/FR4 for many applications, such as:

When you need a laminate with similar properties to G10 that can perform at higher temperatures, G11/FR5 could be the solution. G11 has a similar material makeup to G10 but uses a different kind of epoxy resin system, giving it more mechanical strength and electrical insulation at higher temperatures. Here, the FR5 refers to the flame-retardant version of this material.

The key properties of G11/FR5 include:

G11/FR5 suits many high-temperature applications, including:

G5 and G9 differ from epoxy-based phenolics, as they use melamine resin. Their main advantage is their exceptional arc resistance, which means they can better withstand high-voltage electrical discharges along their surfaces without tracking or damage. G9 is more commonly used, especially for outdoor applications, as it is more weather-resistant.

The key properties of G5 and G9 include:

You can use G5 and G9 for applications such as:

For high-heat, arc-resistant applications, G7 is made with a silicone resin and can withstand the highest temperature among Garolite grades. This makes it suitable for MIL-I-24768/17 GSG-compliant insulation.

G7’s key properties include:

Examples of applications for G7 include:

Here are a few common scenarios to help you decide which Garolite grade is right for the job:

When you’ve selected your Garolite laminate, there are a few points to consider when working with the material.

The first is the abrasive nature of Garolite’s high glass content, which can quickly wear standard tooling. Consider using more durable options, such as solid carbide or diamond-tipped tools.

As you cut Garolite, you’ll need to be wary of delamination and chipping. Worn-out tooling, cutting speed and feed rate can contribute to these issues. G11/FR5 is an example of a material that’s particularly challenging to machine accurately without state-of-the-art machining capabilities.

You must also take safety precautions against the dust that Garolite machining can generate. This includes following OSHA standards for airborne particulates to reduce exposure.

Learn more about Garolite by exploring these FAQs:

G10/FR4 is now the industry standard. The FR4 designation provides vital fire safety, as it’s flame-retardant. Otherwise, the two materials are the same.

The “G” in G10 or any other Garolite grade stands for “glass.” The number following the letter G refers to its different grade, determined by the type of resin.

No, G10 is one of the most commonly used phenolic laminates because of its toughness under load. It sustains its structural and electrical properties in various temperatures and conditions.

Finding the right grade of Garolite laminate for your parts is crucial for their performance. Each phenolic laminate is slightly different regarding the material and how you work with it. To maximize the effectiveness of your part, consider working with a custom manufacturer with expertise in working with all grades of Garolite.

At American Micro Industries, we manufacture made-to-order parts and components for many industries, from aerospace to electronics. Through 30 years of experience, we have developed strict quality standards with the goal of complete customer satisfaction. We offer a range of top-quality phenolic machining services. Request a free quote today.