Parts manufacturing is a crucial element of any product, and your service provider will determine its quality, lead time, accuracy and much more. Besides the part itself, service providers for computer numerically controlled (CNC) machining can differ in how they correspond with you and deliver your finished parts.

Before you enter a new partnership, take the time to research a potential provider and make sure they meet your needs. Below are some factors to consider when selecting a CNC machining provider.

Start by checking how long the company has been in business. If they’ve just started out, they may not have the resources or experience to meet your needs. Ideally, they will have been in business for a few decades, with an established facility and a dedicated team.

Here are some other tips for selecting a reliable CNC machining service provider:

Long lead times can dramatically affect your business and cause a ripple effect across your workflow. Without the needed parts, production could cease and cause problems like bottlenecks and productivity losses. Another example might be a broken part in an assembly line machine. If this part fails, you could be stuck until you get a new one.

Choosing the best CNC machining service depends on finding lead times that fit your needs. Ask about their average turnaround times, and make sure they align with your operation’s demands. Remember to include shipping times in this equation.

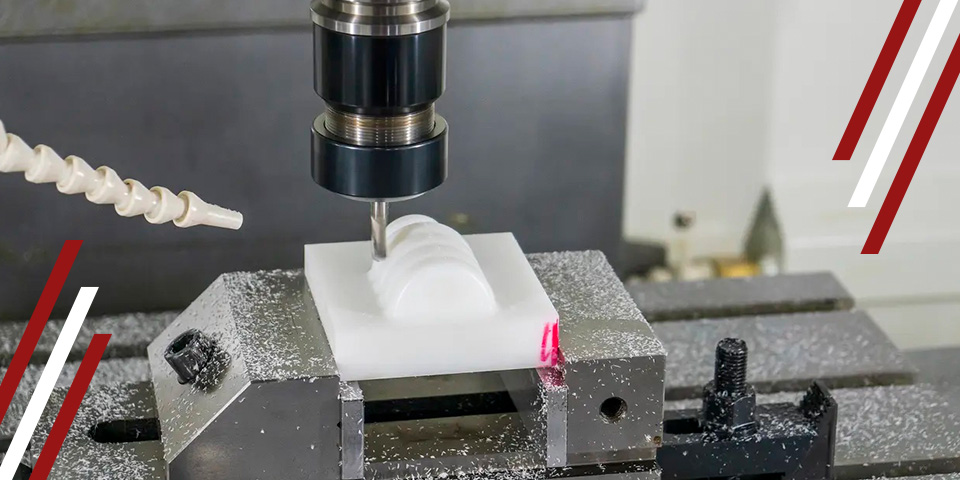

The company will, of course, need to provide the services required to make your product. Consider what kind of equipment and capabilities your parts need. For example, if you need CNC turning, but your provider’s machine can only do CNC milling, you’ll be out of luck. Ask about the types of CNC machining they offer and their equipment specs.

You’ll also want to consider what other methods of machining they offer and if they provide secondary operations like assembly or packaging. These services could help you save money by serving as a one-stop shop, and they’ll likely provide additional quality for your parts by virtue of having a streamlined process and a team that knows the product well.

Some services to consider include:

One more capability to ask about is the provider’s material selection. They’ll need to offer the material your product demands — bonus points if your provider offers considerable variety and high-quality products to choose from. Additional options can give you more flexibility if you need to adjust your design or create a product from a material you hadn’t anticipated when you first partnered with the company. Regardless of your current requirements, a large catalog of materials can provide more options in the future.

Good quality control practices help the provider minimize errors and ensure that the part meets specifications. These practices involve checking the part after fabrication, ensuring equipment performance and maintaining a workflow that adheres to standard operating procedures.

Ask the company about its quality control measures and error rates to gauge its commitment to the process. Depending on your company’s requirements, you may need rigorous quality control and assurance.

Some organizations are limited in their capabilities, especially if contracted on short notice. Consider how flexible your potential partner is. Think about their access to different materials and equipment, and whether they can meet fast turnaround times for parts you need immediately. Can they adapt to changing requirements? Are they responsive to custom requests?

Expert CNC machining services that suit your needs should include flexibility, which offers more resiliency when you must respond to an unexpected problem. They also eliminate the need to maintain partnerships with multiple parts manufacturers.

Even the best manufacturer won’t help you much if you can’t get in touch with them. Evaluate a provider’s approach to communication and support. Do they offer multiple ways to connect, such as phone and email? Is their team attentive and quick to respond? You can usually get more insight into a company’s customer support by reading their reviews online. Look at places like the Better Business Bureau and Google to gain an understanding of their performance.

Make sure your partner is in a good location. If they’re across the country, you may end up paying more for shipping than you’d like. Overseas companies will likely take far longer to ship your parts and may impact turnaround times significantly. Plus, with volatility in the shipping industry, your orders may be more likely to get stuck in transit and delayed.

Consider looking for a company in your region for minimal shipping times. You might also be able to pick up your orders to save on costs and time, and you can talk with someone face to face if needed.

Ask the company about their accuracy, including error rates and tolerances. These metrics will tell you more about their reliability. If you work in an industry that demands high precision, such as aerospace or defense, tight tolerances and good quality assurance are essential. Discuss the company’s capabilities in these areas, paying special attention to their experience with other businesses in your industry.

Your manufacturing partner will play a crucial role in your organization’s success. Spend some time finding the right CNC machining company, and reach out to the experts at American Micro Industries. We’re a veteran-owned and -operated leading manufacturer of made-to-order parts. Customer satisfaction is always our No. 1 goal, and we support it by offering a wide selection of materials and sophisticated equipment.

Our expertise spans many industries, including defense, electronics, aerospace and marine applications, and we offer specialized services like nonmetallic machining and phenolic machining. As your one-stop shop, we’re proud to create new, custom parts, hard-to-find replacements and other components your business might need. Learn more about our CNC machining services today!