To meet the needs of our diverse client base, American Micro Industries works with a wide range of materials and processes. As a partner to everyone we do business with, we specialize in matching the client and the job with the best possible solution.

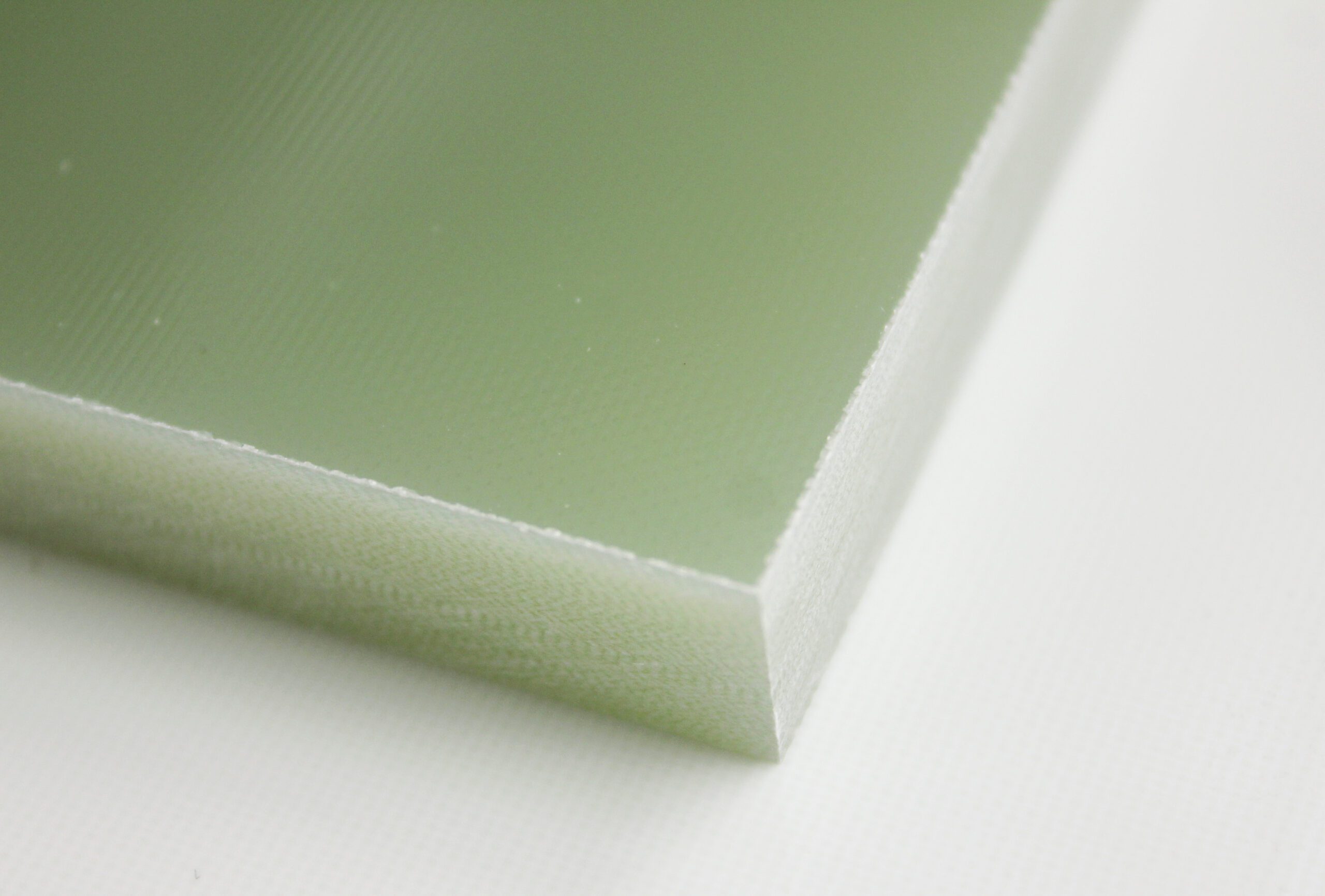

Garolite G10/FR4 is one of the most versatile and widely used laminates for a variety of applications. It’s also one of our most popular material options. On this page, you’ll find detailed information about G10/FR4’s specifications, applications and benefits, as well as a look at some potential alternatives.

G10/FR4’s properties make it an ideal choice for complex, high-precision electrical insulator projects. Electrical insulators restrict the flow of an electrical current, providing protection for anyone who comes in contact with them while ensuring the completion of the circuit and the structural integrity of the product.

Some of the many products that use G10/FR4 material include:

And more. For information about whether or not G10/FR4 is the right choice for your project, contact AMI to speak with one of our engineers directly.

G10/FR4 is just one of the phenolic laminates we work with. Other Garolite materials available for your project include:

For detailed specifications and more information about alternatives to G10 Garolite sheet stock, please contact the AMI office directly.

Micarta ® Phenolics

Various grades of Garolite ® Phenolic material are available.

Contact American Micro Industries today to learn more about our custom G10/FR4 machining and die-cutting capabilities and to request a no-obligation quote. Give us a call at 1-866-774-9353 or fill out and submit our convenient online contact form and we will get back to you as quickly as possible.

G10/FR4 – 36″ x 48″ Sheet Stock