Computer numerical control (CNC) machines help manufacturers get custom parts for their unique applications. This machinery operates on computer-aided manufacturing (CAM) and computer-aided design (CAD) programs to guide highly precise cutting tools. They are go-to solutions for cutting, sculpting and contouring workpieces into specified shapes.

Two common machinery options are a CNC mill and a CNC router. Both feature several axes that enable cutting tools to deliver precise, complete cuts. In this article, we compare these two CNC machine types, the key considerations for each and how to select the right option for your manufacturing needs.

Learn About Our CNC Machining Services

CNC machinery is incredibly versatile, and the right option can drive your team’s operational efficiency. A key characteristic of these tools is their subtractive manufacturing model. They remove sections of material as they work, unlike 3D printing machines, which add new material to a product one layer at a time.

Explore the types of CNC machines below.

CNC milling machines are an excellent option for heavy-duty materials, including the following:

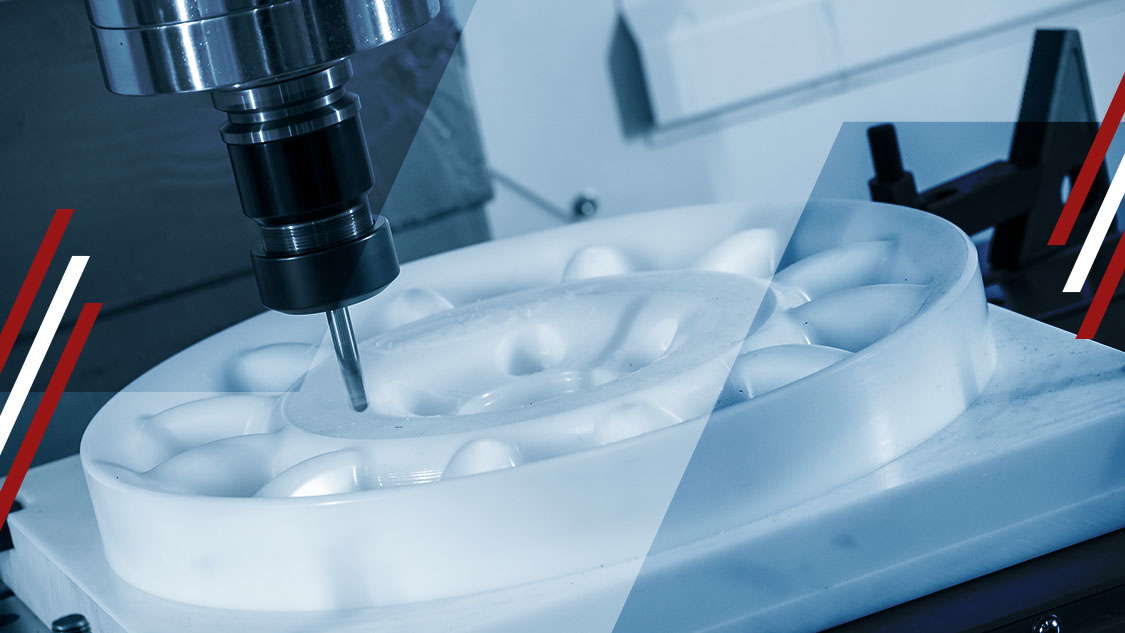

Milling machines are designed for more delicate, highly precise cuts — within a 1,000th of an inch. They are excellent for creating detailed and intricate pieces.

CNC mills operate by moving the workpiece rather than the cutting tools. The machine’s spindle moves on the Z axis while the table controls the X and Y axes. Manufacturers can use over five axes to achieve increased control.

Industries that benefit greatly from CNC mills include the following:

Learn About Our CNC Machining Services

CNC routers work best with softer materials, like foam or plastic. Their cutting tools are especially fast — the router’s revolutions per minute (RPM) significantly outperforms a CNC mill. Despite their efficiency, these machines use rotational speed to drive the tool’s force, resulting in less torque.

A CNC router’s spindle head typically moves along the X, Y and Z axes while the workpiece remains stationary on the table. Most models feature three axes, and some advanced options can have four to six axes to accommodate slightly more complex projects.

Explore the industries best suited for CNC routers:

CNC milling machines and CNC routers perform similar cutting functions with important differences. Manufacturers select between these technologies based on specific project requirements. Understanding the distinctions between CNC mills and CNC routers helps users make appropriate equipment decisions.

Learn About Our CNC Machining Services

In addition to the differences above, CNC routers and mills share some important similarities. These include:

An experienced provider like American Micro Industries can help you determine whether CNC mill vs. router manufacturing is best for your applications. We serve customers needing high-quality, made-to-order parts in various industries, including defense, aerospace, electronics, marine and technology.

We are a veteran-founded company headquartered in Chambersburg, Pennsylvania. Our team prioritizes reliable customer service to ensure you get the CNC machining services you need. We also provide die and laser cutting services. Rely on us for quality components and quick turnaround times.

Learn more about our CNC machining capabilities online, and request more information from American Micro Industries today!