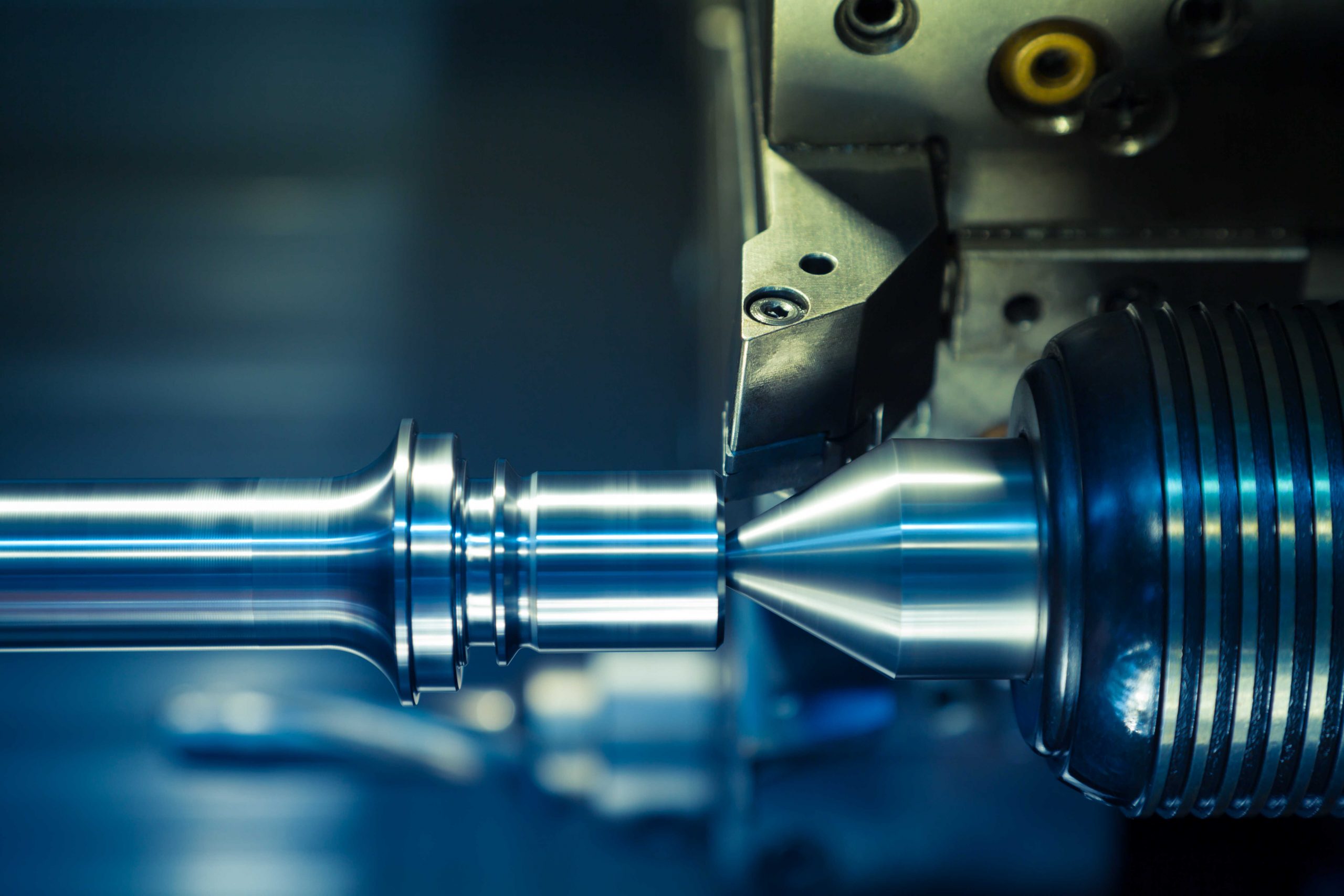

American Micro Industries’ Custom Components division offers elastomer machining services for customers in aerospace, automotive, medical device manufacturing and other industries. We offer fair pricing with no order minimum, making us an ideal partner for prototyping and short-run manufacturing. However, we are fully capable of scaling production upward for larger orders.

We work with many different elastomer compounds to provide options for all our clients. Read on for details about our capabilities and the benefits of elastomers in general, or contact our office directly to request a quote for your upcoming project.

Businesses use elastomers to create a wide range of products. Some of the many machined elastomer components we regularly produce include gaskets, seals, tubing and diaphragms. Virtually all industries require elastomer components, though the highly specialized nature of automotive manufacturing, oil and gas production, medical device manufacturing and aerospace often necessitate custom machined products.

Choosing the right material for a component requires a careful consideration of several factors, including the component’s desired:

Your budget and timeline are also major considerations, as is the component’s regulatory requirements and your internal QC guidelines for acceptable tolerances.

American Micro Industries’ elastomer component machining capabilities include:

We also offer a variety of secondary assembly services, making us a complete turnkey provider for all your production needs. In everything we do, our goal is to match you with the material and the process that will bring your product to life in the most cost-effective and timely manner possible. Our engineers would be happy to review your elastomer component machining requirements and recommend the best way to proceed.

American Micro Industries’ Custom Components division is a longstanding partner to businesses in any industry requiring elastomer and nonmetallic machining. We are a veteran started business with a reputation for integrity and quality in everything we do. We leverage technical expertise and extensive in-house capabilities to deliver total customer solutions for jobs of every size.

Find out how we can help you or request a quote for elastomer machining services by calling our Chambersburg, Pennsylvania, facility at 866-774-9353. You can also use our contact form to get in touch via email.