Play

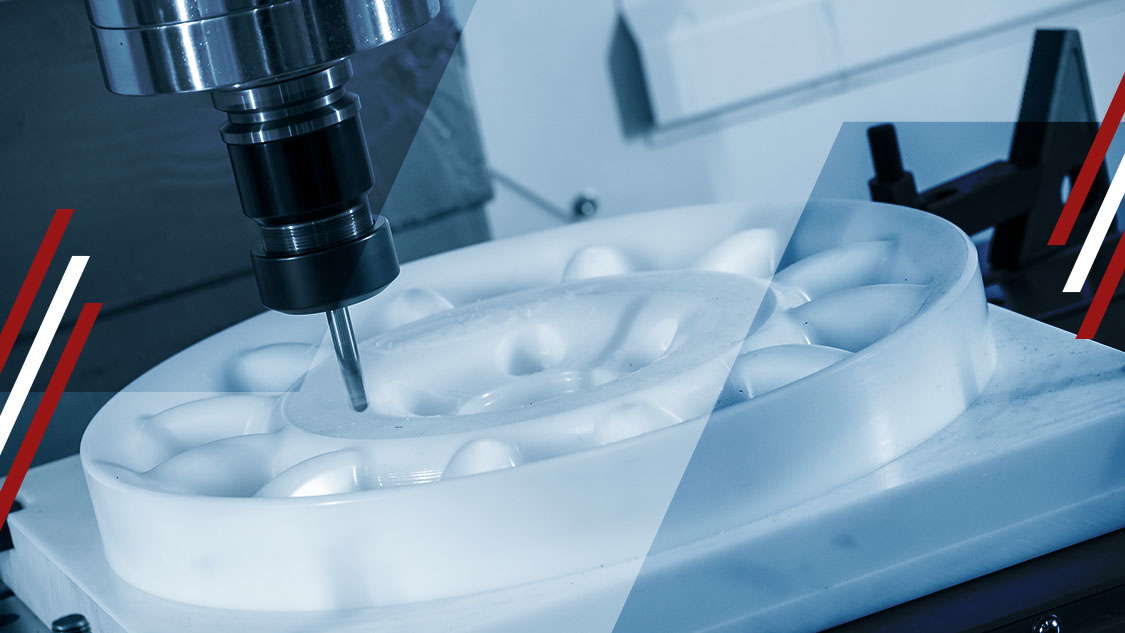

Computer numerical control (CNC) machines help manufacturers get custom parts for their unique applications. This machinery operates on computer-aided manufacturing (CAM) and computer-aided design (CAD) programs to guide highly precise cutting tools. They are go-to solutions for cutting, sculpting and contouring workpieces into specified shapes.

Two common machinery options are a CNC mill and a CNC router. Both feature several axes that enable cutting tools to deliver precise, complete cuts. In this article, we compare these two CNC machine types, the key considerations for each and how to select the right option for your manufacturing needs.

Learn About Our CNC Machining Services

Different Types of CNC Machines

CNC machinery is incredibly versatile, and the right option can drive your team’s operational efficiency. A key characteristic of these tools is their subtractive manufacturing model. They remove sections of material as they work, unlike 3D printing machines, which add new material to a product one layer at a time.

Explore the types of CNC machines below.

What Is a CNC Mill?

CNC milling machines are an excellent option for heavy-duty materials, including the following:

- Aluminum

- Brass

- Fiberglass

- Steel

- Titanium

Milling machines are designed for more delicate, highly precise cuts — within a 1,000th of an inch. They are excellent for creating detailed and intricate pieces.

CNC mills operate by moving the workpiece rather than the cutting tools. The machine’s spindle moves on the Z axis while the table controls the X and Y axes. Manufacturers can use over five axes to achieve increased control.

Industries that benefit greatly from CNC mills include the following:

Learn About Our CNC Machining Services

What Is a CNC Router?

CNC routers work best with softer materials, like foam or plastic. Their cutting tools are especially fast — the router’s revolutions per minute (RPM) significantly outperforms a CNC mill. Despite their efficiency, these machines use rotational speed to drive the tool’s force, resulting in less torque.

A CNC router’s spindle head typically moves along the X, Y and Z axes while the workpiece remains stationary on the table. Most models feature three axes, and some advanced options can have four to six axes to accommodate slightly more complex projects.

Explore the industries best suited for CNC routers:

- Electronics and electrical

- Furniture and cabinetry

- Plastics

CNC Milling Machine vs. CNC Router: Key Differences

CNC milling machines and CNC routers perform similar cutting functions with important differences. Manufacturers select between these technologies based on specific project requirements. Understanding the distinctions between CNC mills and CNC routers helps users make appropriate equipment decisions.

- Accuracy: CNC milling machines deliver superior precision for intricate cutting tasks. The mill tooltip configuration enables high accuracy for complex projects. Medical and aerospace applications benefit from CNC mill precision. CNC routers provide less precise results, making them suitable for basic cutting projects where extreme precision isn’t required.

- Component Type: CNC mills with five-axis capabilities produce high-quality parts with exact specifications. Critical components for medical devices require CNC milling precision. Airplane parts benefit from CNC mill manufacturing processes. CNC routers handle less critical component production effectively when tight tolerances aren’t essential.

- Cutting Area: The workspace dimensions represent a key difference between these machine types. CNC mills provide greater Z-axis depth for deeper material cuts. CNC routers offer wider cutting areas for especially large workpieces. Project dimensions determine which machine provides the appropriate working space for manufacturing needs.

- Machining Speed: CNC mills operate more slowly than routers while prioritizing accuracy. Projects requiring many identical precise parts benefit from CNC milling processes. CNC routers deliver faster cutting speeds for time-sensitive projects. Production timelines influence the appropriate machine selection for manufacturing efficiency.

- Material Compatibility: CNC routers excel at cutting softer materials like plastics. CNC mills effectively handle hard workpieces due to their robust construction. Metal cutting operations require the strength of CNC milling machines. Material hardness directly determines which machine offers the appropriate cutting solution.

Semantic Structure Analysis:

Learn About Our CNC Machining Services

In addition to the differences above, CNC routers and mills share some important similarities. These include:

- Cost-effectiveness: CNC machines are cost-effective manufacturing solutions. They can streamline production processes while supporting advanced precision, enabling increased efficiency. These machines can also operate continuously to maximize output and reduce lead times. Their accuracy allows CNC machinery to reduce material waste, labor costs and production time, ultimately supporting higher profitability.

- Software integration: Another similarity — and advantage — of CNC mills and routers is their integration capabilities. These tools can work with CAD and CAM software to enhance design-to-production workflows. You can use computers to quickly create prototypes and refine designs. Advanced digital solutions can offer data analysis and real-time monitoring to ensure the machine performs as intended, helping to minimize errors and support batch processing.

- Fewer human errors: CNC machines can significantly reduce human error in the manufacturing process, thanks to their CAD software integrations and automated tools. These solutions can help eliminate human mistakes through early error detection and feedback. For applications involving the production of identical parts, CNC routers and mills do not require manual set up. Instead, operators can set a program for the machine to enjoy autonomous and consistent outputs.

- Operator requirements: Operators for CNC milling machines and routers should wear proper personal protective equipment, especially items to prevent hearing loss and respiratory problems. Only trained workers familiar with operating best practices and signs of malfunction, such as material burning, vibrating or jumping, should work with these tools. Skilled operators can ensure the safest and most efficient results from CNC machinery.

- Consistent results: A major benefit of working with CNC mills and routers is their ability to provide consistent results that would be impossible to achieve manually. These tools provide enhanced quality control for product uniformity. Fewer defects and errors mean boosted throughput and higher customer satisfaction. CNC machines offer predictability and better overall efficiency for manufacturing operations.

Turn to American Micro Industries for Quality CNC Machining Solutions

An experienced provider like American Micro Industries can help you determine whether CNC mill vs. router manufacturing is best for your applications. We serve customers needing high-quality, made-to-order parts in various industries, including defense, aerospace, electronics, marine and technology.

We are a veteran-founded company headquartered in Chambersburg, Pennsylvania. Our team prioritizes reliable customer service to ensure you get the CNC machining services you need. We also provide die and laser cutting services. Rely on us for quality components and quick turnaround times.

Learn more about our CNC machining capabilities online, and request more information from American Micro Industries today!