Ethylene vinyl acetate (EVA) is a copolymer material that combines flexibility and strength and has many potential applications in packaging and manufacturing. Based in Chambersburg, PA, we can quickly turn around any project with a high degree of accuracy, as well as respect for your budget and your timelines. Make us your first choice for all your fabrication needs.

EVA is up to three times as flexible as LDPE and demonstrates maximum tensile elongation of 750%. It has a peak melting temperature of 250°F (96°C) and maintains an effective heat seal in low temperatures, too. Other notable characteristics include its clarity, impact strength and puncture resistance. EVA plastic won’t crack when flexed or stressed and isn’t affected by ultraviolet radiation.

EVA’s strong barrier properties make it an excellent choice for use in packaging and sealants. It has no odor, and offers good cling and adhesion. Use EVA to create a blown or cast monolayer film, or blend it with other resins for different applications.

Because of its flexibility, chemical resistance, temperature resistance and other remarkable properties, die-cut EVA can be useful in a wide variety of applications.

EVA polymer is comparable to vinyl and rubber in electrical applications, making it suitable for use as wire and cable insulation or photovoltaic encapsulation and sheeting. Some medical tubing and bag manufacturers use certain grades of EVA in place of PVC.

You can also find EVA polymers in applications such as:

Any situation where you need a rubber-like substance that is flexible and resists challenging environments may be an opportunity to use EVA polymers. If you are not quite sure if EVA plastic will work well for your application, please get in touch with us. Our experts will be happy to discuss the uses of EVA polymer in your industry and help you determine if it is right for you and your business.

To support the above applications, EVA can be easily molded or die cut into different shapes. One notable characteristic is its easily workability. However, expertise is required to manufacture it, particularly in demanding medical device engineering.

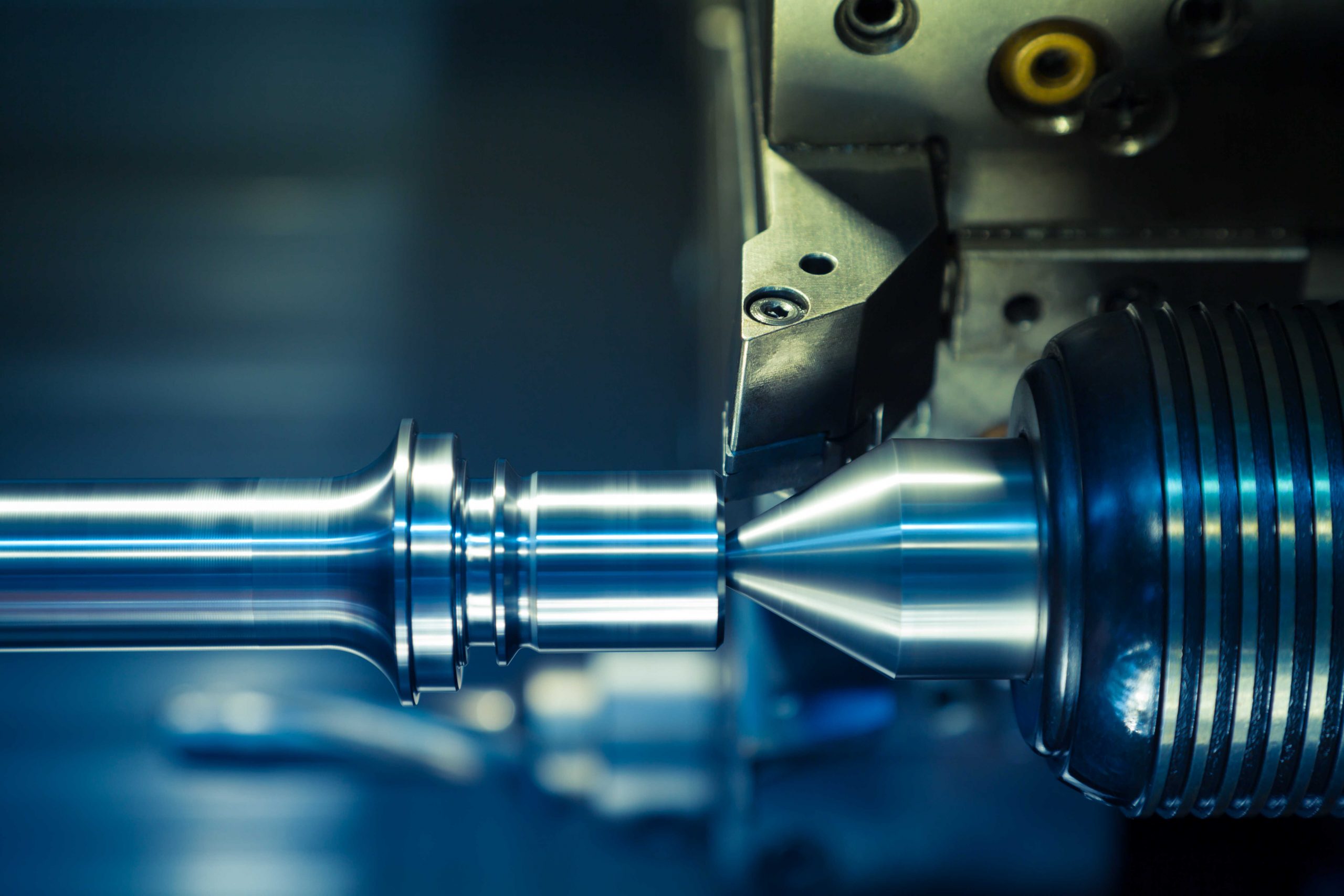

Once you know you want to use EVA plastics in your applications, just let us know, and we’ll do all the work. With our state-of-the-art machines and equipment capabilities, we should have no problem die cutting EVA polymer material into the shapes you need for your insulation, tubing, medical devices — or whatever else you might need flexible, durable polymer material for.

The medical industry is often particularly eager to use EVA polymers because they are very popular with the FDA and can usually meet FDA approval without a problem with little or no additives needed.

Call our team for a free consultation and let us know as much as you can about your applications. We will tell you just how EVA can fit into those applications, how we’ll make it work for you and what the advantages are. We’re always available to answer any questions about this process.

American Micro Industries provides a range of EVA material die cutting services. We excel at meeting high standards for quality in a variety of steel cut die, rotary press and laser cutting processes.

We’re pleased to offer customers free, no-obligation quotes for our EVA die cutting services. We can assist with all aspects of a project. We’re unique in our industry in that we don’t impose order minimums, making us ideal for short-run manufacturing or repair.

American Micro Industries brings the same expertise and commitment to excellence with our EVA polymer die cutting as we bring to all of our machining and other part fabrication services. Our facility is loaded with state-of-the-art machining equipment and a wide range of the best materials for component fabrication available. We have decades of experience on our team to bear on your EVA polymer die cutting and other part creation services.

We bring all of this to you — our expertise, our equipment and our knowledge — at a price that will fit most growing company’s budgets, with a turnaround rate much faster than you may expect.

Find out if EVA plastic is the right choice for your project and learn how we can help you bring your product to market — contact American Micro Industries today.