If you need custom components for the electronics industry, American Micro Industries is your go-to resource. We specialize in manufacturing custom parts, and will identify materials, produce components and ship to you, all from one location. All you have to do is provide us with your specifications. You can also send us parts, drawings or research materials.

We focus on quality and precision and will find innovative ways to meet your project’s unique needs. Each piece gets the rigorous attention to detail that has enabled us to work with some of the most renowned electrical and electronics original equipment manufacturers in the world. We serve a wide variety of industries and are continuously expanding our capabilities.

We only use the highest-quality materials to help us maintain our dedication to exceeding our customers’ needs. We will go above and beyond to ensure we complete your project successfully, on time and on budget. We take pride in every component we produce.

At American Micro Industries, we are truly your one-stop shop for replacement or new custom electronic components. We would love to work with you, so contact us to learn more . To provide you with more information about the services we offer when it comes to custom electronics industry components, we’ve created the following guide detailing some of the electrical insulation materials and processes we use.

G10/FR4, which also goes by the names Micarta and Bakelite, is a type of thermosetting glass-reinforced laminate material with an epoxy resin binder.

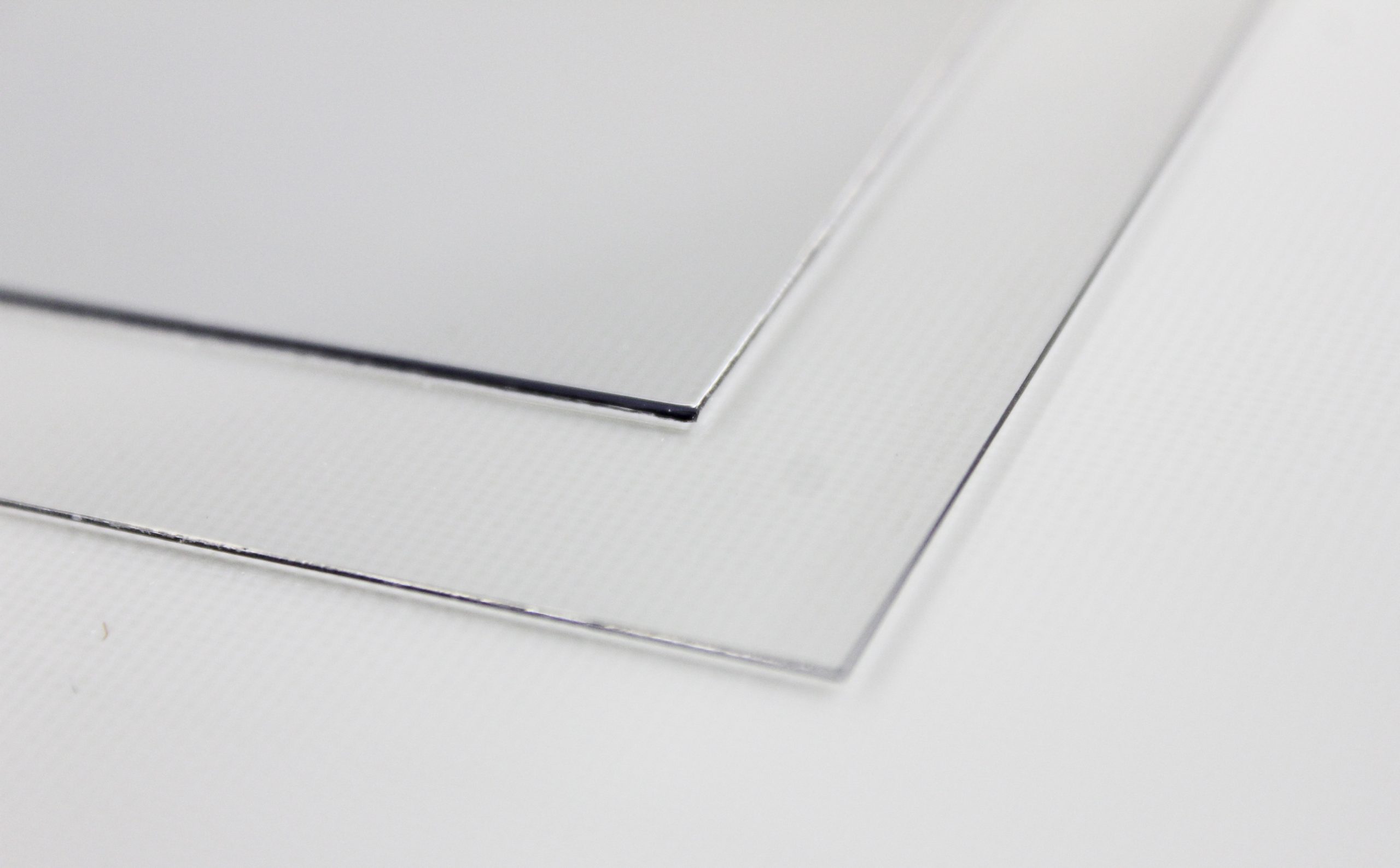

G10 comes in sheets, rods and tubes, and appears in printed circuit boards. It’s made from electrical glass cloth that is alkali-free, to which an epoxy resin is applied using heat and pressure.

The FR portion of the name refers to the fact that the substance is a flame retardant. It has an Underwriter Labs 94 (UL 94) flammability classification of 94V-0 and a maximum continuous operating temperature of 285 degrees Fahrenheit. G10/FR4 is well suited to machining and die-cutting. It has superb mechanical properties at moderate humidity, and our die-cut and machined G10 insulators have a 70,000 pound-force per square inch (psi) flexural strength . Other strength-related properties of G10/R4 include:

G10/FR4 has the highest dielectric strength of all of the materials we offer, at 500 volts per mil. A mil equals one one-thousandth of an inch. Its excellent dielectric strength makes it ideal for uses that require a thickness as low as 0.005 inches.

G10/FR4 has the highest dielectric strength of all of the materials we offer, at 500 volts per mil. A mil equals one one-thousandth of an inch. Its excellent dielectric strength makes it ideal for uses that require a thickness as low as 0.005 inches.

G10/FR4 also has excellent insulation properties, making it useful for various applications. The material holds its structural integrity, even in humidity. You can find G10/FR4 in lighting fixtures, electrical controls, transformers, timers, switches and various other electrical devices and electronic instruments. We can also produce custom die-cut or machined parts for the electronics industry from G10/FR4 to your specifications.

Fish paper, also written as fishpaper, is a kind of fibrous dielectric paper. Electrical-grade fish paper is vulcanized, meaning it undergoes a chemical process caused by the addition of accelerators or curatives to transform a polymer into a more durable material.

This material has an unusual set of characteristics that make it useful for various applications. It is strong, but also lends itself well to forming and punching. Compared to similar plastic materials, it’s more resistant to extreme temperatures. Additionally, it has very high tensile strength, resistance to breaking when under tension and good arc resistance. Exact specifications at 0.62 inches thick are as follows:

Fish paper typically comes in sheets, but might also be sold in coils or rolls designed for automatic punching. This material is ideal for use as an electrical insulation material. Additionally, we can die cut it to make one-off parts for unique applications. Besides its use as electrical insulation, you might find fish paper in electrical instruments, electronic devices, appliances, automotive parts, circuit breakers, fuse tubes, gaskets and more.

Fish paper typically comes in sheets, but might also be sold in coils or rolls designed for automatic punching. This material is ideal for use as an electrical insulation material. Additionally, we can die cut it to make one-off parts for unique applications. Besides its use as electrical insulation, you might find fish paper in electrical instruments, electronic devices, appliances, automotive parts, circuit breakers, fuse tubes, gaskets and more.

Polyester film is a polymer resin, specifically polymer polyethylene terephthalate (PET), which is extremely versatile and sees use in a wide range of everyday products.

Polyester film is both flexible and durable and is highly stable as an insulating material. It has high dielectric and tensile strength. It also has good chemical resistance and can withstand high temperatures, as well as moisture. The material has a UL94 flammability classification of 94VTM-2. Polyester film has the following characteristics:

You can apply a wide range of treatments to polyester film. It can be stamped, punched, metalized, embossed, corrugated, printed on, dyed and coated.

Dura-Lar®, another kind of polyester film, combines properties of polyester film with acetate. Dura-Lar® has excellent heat resistance, durability and dimensional stability. It can be used as electrical insulation, as well as in other industrial applications.

Dura-Lar®, another kind of polyester film, combines properties of polyester film with acetate. Dura-Lar® has excellent heat resistance, durability and dimensional stability. It can be used as electrical insulation, as well as in other industrial applications.

Polyester film has many various possible uses. Besides being used as an electric insulator, it is also employed in product packaging, as a window film to strengthen glass, in printing, labeling and the manufacturing of medical devices. American Micro Industries can provide polyester film in 20-inch by 50-inch sheets or create custom machined or die-cut parts. We also offer polyester film with and without a pressure-sensitive adhesive, or PSA.

In electronics manufacturing, you need to protect against electromagnetic interference (EMI) and radio frequency interference (RFI), terms that refer to electromagnetic noise and its effect on a component. EMI and RFI shielding are crucial for consumer electronics, aerospace, defense and other manufacturing sectors.

EMI and RFI shielding can prevent a device from creating unwanted inference, protect a device from outside interference and contain or exclude RFI and EMI while pressure-sealing a device and ground an electronic device. American Micro Industries can provide expert fabrication and quality materials to create the shielding capabilities your project requires.

There are many shielding materials, and they each work best in different applications. Some typical materials used for shielding include:

At American Micro Industries, we can create unique components to your exact specifications. Our extensive in-house manufacturing capabilities have made us a trusted source for custom-made parts.

We produce parts for a variety of industries, including those that require extremely precise and high-quality specifications such as the aerospace, military and automotive manufacturing sectors. The range of materials and production methods we offer enable us to provide a wide range of unique components. In fact, we have a 90 percent acceptance rate for custom specifications.

We use a number of techniques to deliver the perfect solution for your projects’ requirements, including:

Another aspect of our business that has contributed to our success is our dedication to 100 percent customer satisfaction. We use quality materials and precise manufacturing processes to get you the results your project requires. Because we value relationships and communication, our account managers will walk you through the process of acquiring the component or material you need, and be available to answer any questions you may have. We also do not require a minimum order amount, and we have a low fee for custom tooling.

If you need custom components for the electronics industry and are interested in our services or want to learn more about what we offer, request a free quote or more information using our online form. You can even upload your specifications and technical drawings for your project along with your request. Get started today!