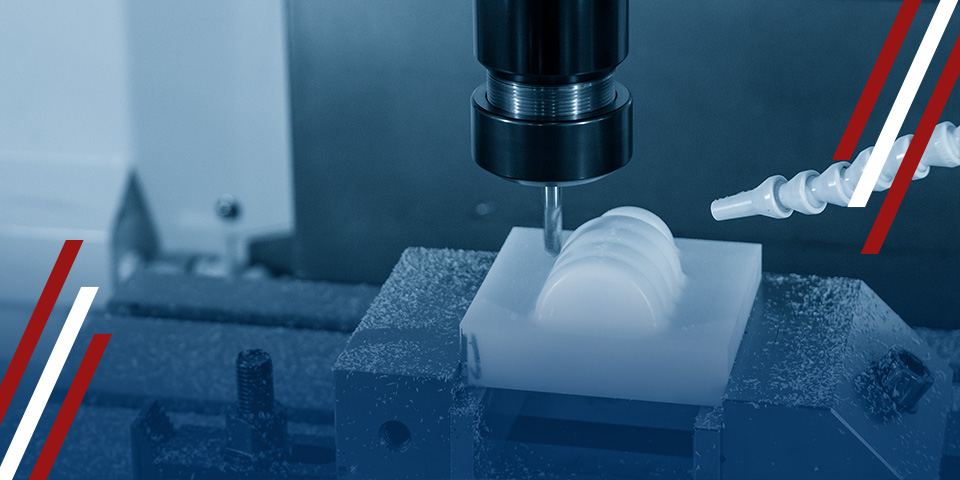

Computer numerical control (CNC) machining is instrumental in creating parts for the medical, aerospace, transportation and military and defense industries. At American Micro Industries, we provide custom CNC machining services and materials that allow us to bring your designs and products to life. We provide everything you need for your custom parts — whether you require materials, CNC machining services or both.

Learn more about our custom CNC machining services and materials. Contact American Micro Industries to explore our quality CNC machining solutions.

We offer a range of CNC machining services for various industries and applications:

We work closely with your engineers and designers to create prototypes. Our design engineers may also make the CAD drawing and submit it to you for approval.

We will produce the first piece for your approval. The prototyping phase is the ideal time to discuss surface finishes, additional treatments and coatings.

Once you are satisfied with your prototype, we will produce your finished components and include in-process inspections and post-processing quality checks.

At American Micro Industries, we strive to make CNC machining simple by offering these benefits: